chassis

From single components to highly complex assembled products.

Chassis: our solutions

Since the late 70', here in Streparava we design, test and realize suspension components for cars, commercial vehicles, buses, trucks and farming machines.

The highest quality standards. Always.

We commit ourselves with extreme care in the manufacturing process, thanks to the experience and competence acquired in all technologies and materials used in our field - steel forgings, cast iron, aluminium forgings, castings, aluminium extrusions, and sheet metal - having at our disposal highly automated machining and assembly lines, dedicated to the different products, always assuring the traceability of our components and process parameters.

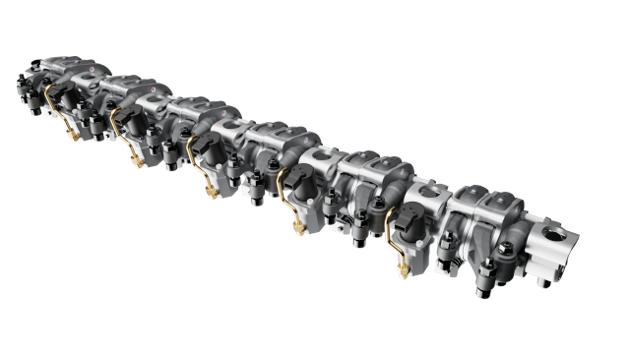

In Streparava we are able to supply both single components, and fully assembled solutions with a very high degree of complexity, acting as system supplier, ensuring control on all critical characteristic of the assembly phase and the option to perform functional test runs.

And if we're talking about suspensions...

Since 1978 in Streparava we've been developing, testing and producing independent front suspensions for light commercial vehicles, realizing the final assembly of the complete suspensions on dedicated lines, with automated controls and recording safety related parameters. More than 3.000.000 parts have been delivered, managing a complex bills of material with more than 200 components and tens suppliers located worldwide: numbers that witness our recognized experience in the automotive field.

… more than ever looking toward the future

In the automotive business, the future is “electric”. That's why from 2010 we've developed, tested and patented an independent suspension system for zero emission vehicles - the new generations of electric commercial vehicles and small urban buses.

In the automotive world, the future will also be “light”. That's why, beside working aluminum components for suspensions, we have designed, validated and patented solutions for suspension control arms in extruded aluminum or HPDC cross beams, gaining benefits in terms of weight reduction up to 50% compared to the original design.

Production

technology e process development

Streparava follows a policy of constant update regarding strategic competences, tools, equipments and market processes, applying the most modern methods of industrial automation and digital transformation.

Plant

Presence in the world

With 9 facilities in the world, Streparava produces chassis and powertrain components with an high degree of precision, supplied to the major OEMs for motorcycles, automobiles, buses, industrial and commercial vehicles.