The digital chassis for autonomous driving is born

25.07.2019

The Automotive Revolution

New skills for the future of the automotive world

The macro trends that the automotive world is going through (electrification, autonomous driving, vehicle digitalization, new mobility models) will have a very high impact both on the finished product and on the supply chain, radically changing the needs of vehicle users and therefore of the OEMs (original equipment manufacturer).

In particular a growing role is being observed for first level suppliers such as Streparava (the so-called Tier1) in the definition and development of increasingly broad, complex and multidisciplinary vehicle systems; we will therefore have to talk at the same level as the OEMs to manage the complexity and variability of constantly evolving world, with solutions capable of giving answers to the main technological trends and more generally to the new business models of mobility services.

In order to meet the challenges of the next decade and always ensure high levels of competitiveness, it is therefore necessary to both extend our scope of action, conceptually up to the chassis complete with traction systems, and integrate it with new smart and electronic skills.

New investments, new opportunities

In line with its vision (“Key innovative solution provider for the mobility of the future”), Streparava decided to explore the opportunities arising from the evolution of the sector, combining them as a further competitive lever to the historical company know-how, entering the capital of e-Shock a young company specialized in electronic solutions and software for traction, braking, steering and suspension control. E-Shock is an innovative SME supported and developed by the “Business Factory” e-Novia to become today one of the most dynamic and innovative companies in the application of artificial intelligence to vehicle dynamics.

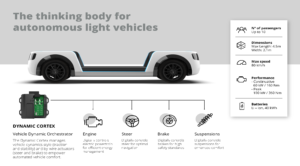

The integration of the Streparava mechanical know-how with the electronic and software one of e-Shock has given life to the project of a Digital Rolling Chassis, that is a complete electrically-driven chassis with integrated autonomous driving features capable of enabling a variety of uses and services, intended for light vehicles that will operate in urban, private and industrial contexts.

The multiple applications of the Digital Rolling Chassis

This “digital chassis” will be the basic structure for the subsequent “dressing” of the vehicle according to its possible use, but it already integrates inside all the vehicle systems, sensors, controls and drives able to allow new mobility players to adopt the integrated solution of vehicle control and autonomous driving; a solution able to offer high flexibility, reduced investment and time-to-market.

This solution aims to facilitate the access to the world of mobility services to new players, relieving them of the specific design complexity of the “automotive” product and leaving them ample room for imagination about how our digital chassis can be dressed

a basic chameleon structure able to become from time to time minibus for shuttle service, robot-taxi, logistics service, street shop, itinerant office, goods delivery, operating machine for services for municipalities, car-sharing services and much more.

The heart of the Digital Chassis

Among the characteristics that we have identified for this wide range of vehicles, maneuverability is an important parameter, seen as the possibility of moving in extremely restricted spaces; this feature can be achieved through the development of suspension systems with high components modularity and high steering angles, both on the front and rear axles. In the perspective of an autonomous vehicle, in fact, the same distinction between front and rear loses its meaning, with consequent implications on the design choices we are going to make on braking systems, steering systems and vehicle dynamics settings to fully enable a vehicle that must be bi-directional.

The streparava experiences in the latest years in the field of lightening will flow into the development of the suspension system and the complete chassis, to guarantee lightness, load capacity and at the same time modularity and flexibility as the application changes.

The chassis will be integrated with the electric traction system, a gearmotor installed on one of the two axles, sized and chosen according to the speeds, slopes and transportable masses, a battery pack sized according to the target autonomy and all the systems necessary for the correct functioning of the running chassis.

Motion Control and the evolution of autonomous driving

E-Shock will implement its own motion control algorithms to “give life” to the chassis through by-wire controls (steering, brakes and traction), communicating with an autonomous driving system capable of seeing and interpreting the surrounding reality. Motion Control then translates into movement and action the inputs derived from the navigation system, in consideration of the dynamic conditions of the vehicle and the comfort of use; to make an analogy, the navigation system behaves a bit like that part of the brain that perceives what surrounds us and decides where to go, while Motion Control like that part of the brain that defines how to move, giving instructions to the muscles and the body on strength, speed, intensity and motor coordination in general

This project, considering the range of content, will represent itself a whole panorama of skills and technological solutions to be offered in support of more structured and traditional OEMs as well as new players, to be exploited as a further competitive lever.

The concept mock-up will be presented in January at CES 2020 in Las Vegas, the most important global event on technological innovations, while the fully running prototype will be ready in the spring of 2020.

This is a very important operation, not only for streparava and e-Shock, but also for the evolution of the Italian industrial sector that invests in frontier technologies such as autonomous driving.

NEWS

Plant

Presence in the world

With 9 facilities in the world, Streparava produces chassis and powertrain components with an high degree of precision, supplied to the major OEMs for motorcycles, automobiles, buses, industrial and commercial vehicles.